|

Mini Cryogen-Free Magnet SystemIntroduction of MCFM System from Cryogenic Limited companyMini Cryogen-Free Magnet System is a physical device used for production of strong magnetic field created by superconducting coil. The system combines the latest cryogen-free technology with sophisticated measurement techniques providing a versatile, powerful investigative device achieving low temperatures and high magnetic fields without the direct use of liquid helium or nitrogen. Closed loop system uses helium gas for refrigeration of the superconducting magnet and the sample. The instrument is designed for the measurement of magnetic properties using VSM (Magnetic Moment and AC Susceptibility) and electrical properties (Resistivity and Hall effect). Measurement range is for magnetic field from – 9 T to 9 T and for temperature from 1.6 K to 400 K. Instrument is comprised of the following components:o A cryostat incorporating a cryocooler, superconducting magnet and a variable temperature sample space. o Rack incorporating electronics for control and monitoring of the cryostat and any measurement options. o Measurement system software. o Sample probes. o Measurement options (VSM, Resistivity). General comments:o Use QUIT or STOP buttons for close the windows. It could avoid software freezing. If software freezes, use STOP button in the main window and start by button with arrow. If does not help, use X symbol in right top corner. If does not help, remove window from list of processes (CTRL+ALT+DELETE). If does not help, remove all windows from the Cryogenic Ltd software and restart it. o When restart the software, please control value of AC field frequency (DAQ control, AC susceptibility). Since 7th April 2017 it should be 21 Hz (for different frequency is different VSM coils factor). o Switch ON the button Preamplifier (it is green for ON) only in the case that the Preamplifier is included into the system. The amplified signal will be divided by approximately of 500 to get correct value of magnetic moment.

o When restart the software and select VSM measurement mode, please control T_sample. In case of high deviation (e.g. 200 K instead of 300 K), you must select correct calibration file. In rack, Lake shore model 350 put: Input Setup - Select Input : B : Probe - Curve : 24 X117028e instead of 22 (moving in options via ENTER, ARROWS, ESC). Changes in setup20172017_10_23 - System alignment (JL). 2017_10_03 - System alignment (JL). 2017_09_26 - System alignment (JL). 2017_09_07 - System alignment (JL). 2017_07_20 - Director Jeremy Good from Cryogenic Ltd. and Jiří Melicherčík from Testovací Technika visited our lab to see our MCFMS. System alignment (JL). 2017_07_19 - System alignment (JL). 2017_07_17 - System alignment (JL + RK). 2017_07_04 - System alignment (JL). 2017_06_19 - Recharging He dump/He pot by Helium of 99.99% purity. 2017_06_08 - Replaced VSM by upgraded version from Cryogenic Ltd (double table, manual height adjustments, shorter VSM rod). System alignment. 2017_04_12 - Flushing and recharging He dump/He pot by Helium of 99.999% purity. 2017_04_07 - The system was cleaned, controled and newly fitted by Yury Bugoslawsky from Cryogenic Ltd. Replaced AC field frequency from 16 Hz to 21 Hz. Stopped using auto centre utility. 2017_03_31 - He bottle included into the Gas cabinet in the Technical room. There are two He bottles (left opened, right closed), automatic pressure switching is available. This change was performed by CVSC firm. 2017_03_24 - The Turbo HiCube was replaced by another Turbo + rotary pump in the Technical room. 2017_03_22 - Radovan Klusak (CEITEC Nano technician) made better sealing of compresor and water circuit for Cryogenic in the Technical room. 2017_01_22 - Replaced AC field frequency from 20 Hz to 16 Hz. 2016_12_20 - re-initialised the magnet power supply (AD, JL). 2016_12_19 - Andrea Iagallo from Cryogenic Ltd reinstal the new version of software. 2016_11_29 - Training of KF, VK, MV, JL (AD, ZL). 2016_11_22 - First testing measurements of Ni Sphere (AD, ZL, JL). 2016_11_16 - Preparation for restart the instrument after long time when was in Cryogenic Ltd (AD, ZL, JL). 2016Pumping the system/warming or cooling20182018_06_18 11:52 - start pumping the vacuum chamber (the turbo + rotary pump put back in the technical room). 2018_06_14 - stop pumping the vacuum chamber (the turbo + rotary pump borrowed to the 2nd Cryogenic in the bottom lab). T He pot start growing since 9 h (went to 12 K, next days only about 8 K). 2018_05_30 12:30 - start pumping the vacuum chamber (start the turbo + rotary pump in the technical room, opened vacuum chamber valve). 2018_05_14 12:30 - warming the system? Reason: Black-out in whole CEITEC lab. 2018_05_09 17:00 - 2018_05_10 9:00 - cooling the system (compressor in the Technical room was switched ON by us). 2018_04_23 16:30 - 2018_05_09 17:00 - warming the system (compressor in the Technical room was switched OFF by us). Reason: probe felt down and opening the chamber for removing probe is planned. 2018_04_11 - refill Helium gas in VTI from the standard He bottle. 20172017_12_18 - turbo + rotary pump in technical room was shortly switched off, pc + rack and electrical power in whole lab was shortly switched off. After switch on, everything looks normal. 2017_09_25 10:01 - 2017_09_26 10:02 - cooling the system (compressor in the Technical room was switched ON by us). 2017_09_19 19:22 - 2017_09_25 10:01 - warming the system (compressor in the Technical room was switched OFF by us). Reason: planned switch off the cooling circuit in whole CEITEC Nano labs for 3 days. 2017_09_08 17:30 - - pumping the system by Turbo. 2017_06_19 - 2017_06_20 - cooling the system (compressor in the Technical room was switched ON by us). 2017_06_06 17:17 - 2017_06_19 - warming the system (compressor in the Technical room was switched OFF by us). 2017_05_23 9:30 - 2017_09_08 13:15 - pumping the system by Turbo. 2017_05_09 15:40 - 2017_05_12 15:23 - pumping the system by Turbo. 2017_04_28 18:05 - 2017_05_03 18:37 - pumping the system by Turbo. 2017_04_12 10:00 - 2017_04_13 11:24 - cooling the system (compressor in the Technical room was switched ON by us). 2017_04_10 13:14 - 2017_04_12 10:00 - warming the system (compressor in the Technical room was switched OFF by us). 2017_04_07 11:00? - 2017_04_13 11:42 - pumping the system by Turbo. 2017_03_22 16:46 - 2017_03_23 10:40 - cooling the system (compressor in the Technical room was switched ON by us). 2017_03_20 17:30 - 2017_03_21 10:03 - warming the system (compressor in the Technical room was switched OFF by us). Shortly was the system cool down 2017_03_21 17:18 - 17:29 but water was detected in the technical room under compressor. 2017_03_20 11:30 - 2017_03_23 10:03 - pumping the system by Turbo HiCube. 2017_02_21 - 2017_02_27 - failures of cooling circuits at 21st and weekend (25th, 26th) - system was warmed up to room temperature and cooled down on Monday 27th (AD). 20162016_12_28 11:35 - 2016_12_28 23:00? - cooling the system. 2016_12_27 - 2016_12_28 11:35 - cooling circuit OFF, warming the system. 2016_12_12 10:15 - 2016_12_12 23:00 cooling the system. 2016_12_10 - 2016_12_12 10:15 - cooling circuit OFF, warming the system. 2016_12_07 16:00 - 2016_12_0? cooling the system. 2016_12_06 9:00 - 2016_12_06 15:00 - cooling circuit OFF, warming the system. Detected problems20182018_06_18 (JL) - It was found that the turbo + rotary pump was borrowed to the 2nd Cryogenic in the bottom lab. T He pot start growing since 14th June, 9 h (went to 12 K, next days only about 8 K). It was solved by new pumping of vacuum chamber by turbo. Restart pc helped to start internet connection. 2018_06_16 (MD) - It was not possible to cool down the sample below 10 K. In addition, the temperature of He pot was too high (around 8 K). Internet was not working. 2018_05_31 (JL) - It was not possible to cool down the sample below 8 K during transport measurements of superconducting thin film. Change of He flow did not help much. It was solved - high current in sample (0.01 A) caused extra heating. It was ok with lower current (0.0001 A). 2018_04_23 (JL) - Sample inside the transport probe felt down to chamber. Therefore the system was warming up. 2018_04_19 (JL) - problem with stability of temperature of sample around 400 K (VSM). It occurred probably due to low rate of warming/cooling in maximum temperature (0.13 K/min). 20172017_11_23 (JL) - VTI pressure is not stable. Originaly was 3.5 mbar after improvement to 9 mbar is decreasing. The same detected in following days for several months (e.g. 4.12.2018 pressure was 0 mbar, put on 9 mbar). 2017_11_14 (JL) - strange oscilations in magnetic moment (VSM). Probably low power baterry of preamplifier. 2017_11_08 (AD, MK) - some errors in software - restarted. 2017_09_08 (JL) - Gas cabinet off due to short (second) blackout of electric power in the city. Relay for gas cabinet power in the optical lab was off. One cable was damaged. Turbo and rotary pump were off too. 2017_07_19 (JL) - Problem with field B_analog /= B_digital. Restart of software helped. 2017_07_11-14 (JL) - After finishing the last measurements T_magnet arose to 4.95 K. Pressure on VTI only 5 mbar. Corrected to 10 mbar via Needle valve. Since 2017_07_14 morning are temperatures of Magnet and He pot below 4.2 K. 2017_07_05 (JL) - Problem with field. Output, T = -0.00001, but B_analog = B_digital = -1 T. 2017_06_28 (MZ, JL) - Problem with strange value of sample temperature (T_sample is about 200 K, should be 300 K). It could be corrected manually via Lake Shore model 350 - select correct calibration file for B: probe - 24 X117028e (info from 4th July 2017). 2017_06_05-09 (JL) - Some problem in gas cabinet - false alarms of gas leakage. Helium for flushing airlock stopped. 2017_05_23 (AD) - He pot temperature went to 10.6 K, magent to 8.9 K, AD started pump the system, tempere went down below 4.2 K. 2017_05_23 - He pot temperature was going from 3.8 to 4.2 K 2017_05_12 (JL) - Since the last pumping, He pot temperature has very low value only 3.6 K, in every time before it was close to 4.1 K! 2017_05_09 (JL) - 14:33 growing temperatures of Magnet and He Pot after set positive field. Start rotary pump for Turbo (15:00), start Turbo (15:05), opening Vacuum Chamber valve (15:35-15:40) and start pumping.

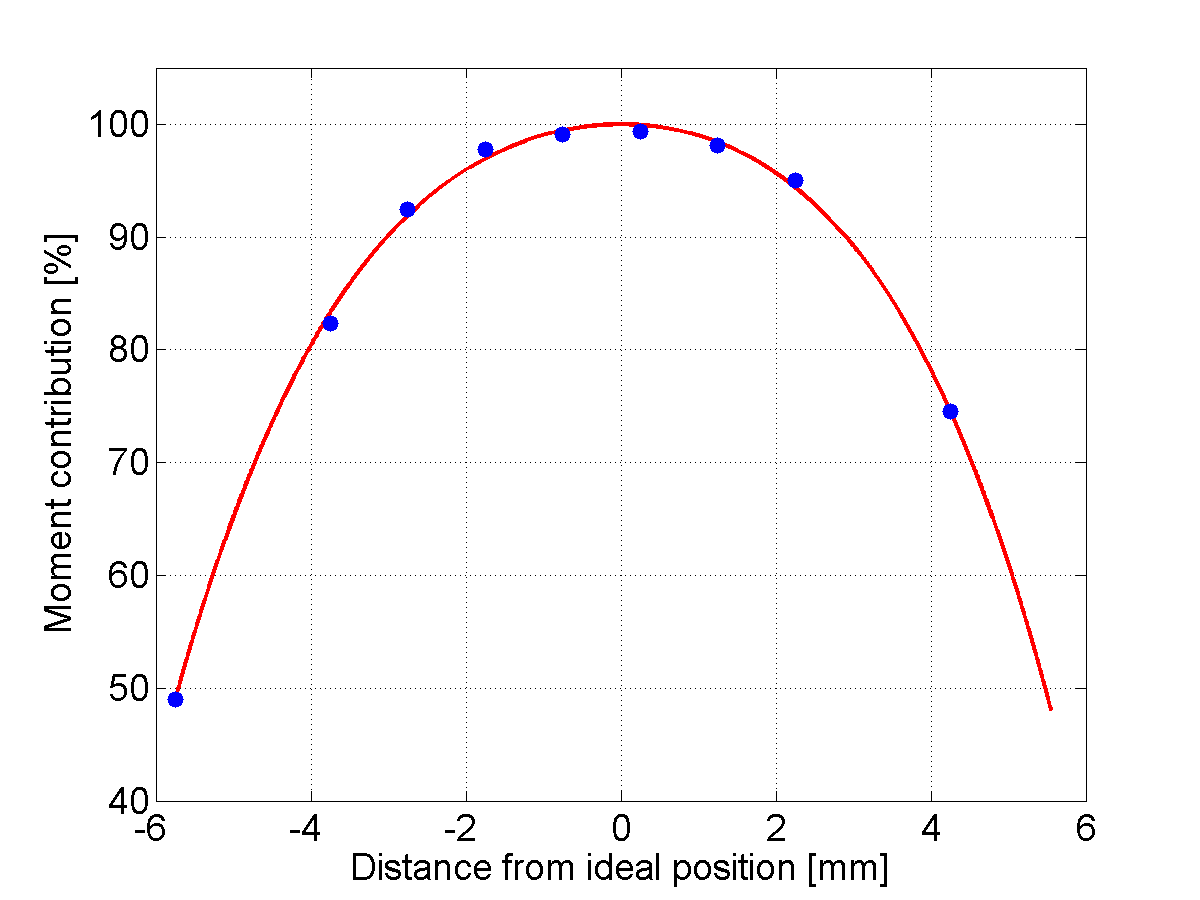

2017_04_28 (JL) - 10:50 growing temperatures of Magnet and He Pot after set positive field. Start rotary pump for Turbo (17:15), start Turbo (17:19), opening Vacuum Chamber valve (18:05-18:10) and start pumping. 2017_04_09 (JL) - growing temperature of He Pot. 2017_04_07 (YB+AD+JL) - 11h growing temperature of He Pot after set positive field. Start rotary pump for Turbo, start Turbo, and opening Vacuum Chamber valve and start pumping. 2017_03_23 (JL) - 10:03 stop pumping by Turbo HiCube. 2017_03_22 (JL) - 16:46 start cooling the system (compressor in the technical room was switched ON). Radek Klusak repaired the cooling water during morning. 2017_03_21 (JL) - 11:18 start cooling the system (compressor in the technical room was switched ON). 17:29 Compressor swithed OFF - small area with water under the "cube" of compressor. 2017_03_20 (JL) - 11:30 start pumping by Turbo HiCube, 17:30 start warming the system (compressor in the technical room was switched OFF). 2017_01_25 (KF) - Evident difference between B_analog and B_digital (different ramp between -2 and 0T, constant B_digital in 0T). 20162017_01_02 (KF, JL) - Strange oscilations in VTI pressure (5-13 mbar) 2017_01_28? (PF) - Strange oscilations in VTI pressure (10-23 mbar) Difference between bad and correct position of sample in pickup coils

Raw DATA from 2017_04_07 - Ni sphere, measurements obtained by Yury Bugoslawsky History of VSM coils factorsAs we found during summer 2017, the signal depends also on orientation of VSM head, therefore, the VSM coils factor could vary significantly (position of VSM head was changed)

* set it in Edit system configuration, Hardware settings, VSM Show configuration = VSM configuration, VSM coils factor, V/emu, + Maximum field, must be 9.01, **set it in DAQ control, AC susceptibility, AC field frequency (Or Edit system configuration, Hardware settings, VSM Show configuration = VSM configuration, VSM frequency, Hz) History of differences between B_analog and B_digital

List of users and other persons, their abbreviationsOC - Ondrej Caha MD - Meena Dhankhar AD - Adam Dubroka KF - Katerina Fabianova PF - Pavel Fris MH - Michal Horky MK - Michal Kiaba RK - Radovan Klusak VK - Viola Krizakova AK - Anna Kulkova JL - Jiri Liska ZL - Zuzana Liskova MU - Michal Urbanek VU - Vojtech Uhlir MV - Marek Vanatka SV - Stanislav Valenda MZ - Marek Zboncak XZ - Xixia Zhang Webpage prepared Jiri Liska, last updated - 2018, June, 28 |